charpy impact test toughness|charpy impact test sample : companies The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is . Resultado da 25 de ago. de 2023 · Akiko Matsuura is a Japanese-born English drummer and vocalist. She is most famous as the ex-girlfriend of actor Charlie Heaton. She is also a mother of one.

{plog:ftitle_list}

Resultado da The Oracle Temple is where the lmperial City's citizens worship and make offerings to their gods. After so much turmoil, destruction, and reconstruction, the Oracle Temple now stands as the center of the Imperial City's faith. Countless commoners come here daily to pray to the gods, despite most of .

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

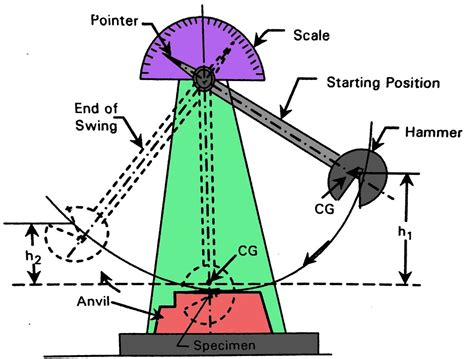

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .

A remarkably enhanced Charpy V-notch impact toughness was demonstrated in these laminate DP steels, 400–450J at strength level of 1.0–1.2 GPa at RT and 400J at −40 .

charpy impact test sample

On the other hand, due to simple operability of the impact test, the relation between impact toughness and fracture toughness has been investigated over the past decades. Rolfe-Novak-Barson [10], [11] established an empirical formula between Charpy impact energy and fracture toughness through analyzing numerous steels with different strength . Factors Than Can Affect a Charpy Impact Test 1. Yield Strength. In general, as a material's yield strength increases, its impact energy will decrease. In other words, materials with higher yield strength will generally . The Charpy impact test was conducted to examine the influence of salt spray. The impact strength CVN show decreasing trend with increase in exposure hours. The data of yield strength σ y s and the impact strength CVN were used to .Impact data: the room temperature Charpy impact strength of extruded and forged section given the recommended heat treatment of 2 h/1150°C/WQ + 8 h/800°C/AC is in the region of 111 J. Long-term embrittlement has been investigated by room and elevated temperature Charpy impact testing of extruded and forged section given the recommended heat .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . The Charpy test is most commonly used to evaluate the relative toughness or impact toughness of materials and as such is often used in .

charpy impact test procedure

In order to reveal the toughness of our designed steel, standard Charpy V-notch impact samples were prepared. Ultrahigh Charpy V-notch toughness of 300–450J was achieved with strength as high as . A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. The standard test specimen is described in ASTM E23. It has a V-shaped notch cut into it. It is oriented so that it is simply supported on both ends .

For these cases, the remedy involves making use of fracture toughness estimates from simpler and readily available mechanical tests, such as the Charpy V-notch (CVN) impact test [7], [8], the drop-weight test for measuring the nil-ductility transition temperature (NDTT) [9], [10], [11] and the dynamic tear (DT) test [9], [10], [12]. Because of .

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . This absorbed energy is a measure of a given material’s notch toughness and acts as a tool to study temperature-dependent ductile-brittle transition.The two most common methods to determine toughness include: Izod and Charpy Test. Key principle These impact methods are based on the common principle of: . Note: The result of the impact test is reported in energy lost during the impact per unit of specimen thickness (such as ft-lb/in or J/cm). Test results, .

As was written, toughness can be measured by the Charpy test or the Izod test.These two standardized impact tests, the Charpy and the Izod, are used to measure the impact energy (sometimes also termed notch toughness). The Charpy V-notch (CVN) technique is most commonly used.Impact Toughness. The impact toughness (AKA Impact strength) of a material can be determined with a Charpy or Izod test. These tests are named after their inventors and were developed in the early 1900’s before fracture mechanics theory was available. Impact properties are not directly used in fracture mechanics calculations, but the . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .

compression tester for leakdown test

Charpy Impact Testing, also known as the “Charpy V-notch test,” is a standardized test method used to determine the impact toughness of materials, particularly metals. It assesses a material's ability to absorb energy during fracture when subjected to a sudden impact. The V-type impact test was carried out with a square having dimensions of 14 × 14 mm processing. . Effective grain size and charpy impact properties of high-toughness X70 pipeline steels .

The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer. The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.

How is the Charpy Impact Test performed? In a Charpy impact test, a notched (U-notch, V-notch, and double notched) material specimen is clamped in a test apparatus, and a pendulum is released to strike the notched area. The energy the material absorbs before its fracture is measured, indicating its impact strength.The Charpy impact toughness of aluminum alloys is reduced via introduction of the reinforcement (Singh and Lewandowski, 1995; Lewandowski and Singh, 1996). Figures 7 and 8 summarize recent data obtained on 2XXX, 6XXX, and 7XXX materials in both unnotched and notched conditions, respectively. Although the data are somewhat limited in comparison to the . As a result, the complex CTOD test, which is costly, can be determined by a simple low-cost Charpy impact test, providing guidance for the widespread application of Q690 high-strength steel in low . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures. Learn more about the .

compression tester for marine diesel engines

The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good Quality Control (QC) method, and is globally accepted. . Schematic of a Typical Charpy Impact . Charpy impact testing was performed on the series of machined specimens with sub-size cross-section to obtain values of CVN impact energy. Fracture toughness test method according to ASTM E1820 .Characterizing the toughness of a material is done in several ways. The most common method is the notched-bar impact test for which two types of specimens prevail, Charpy and Izod. By subjecting a specimen to an impact load, it will fail if the load exceeds the .The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.

Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.

charpy impact test pdf

Idol Kouhosei – 01. Hentai online com legendas em portugues com censura e sem censura. Assista milhares de videos hentai completos e completamente grátis!

charpy impact test toughness|charpy impact test sample